The Defense industry is constantly challenged to be ahead of the curve when it comes to protecting the front line.

3D Printing:

The quality and strength of materials available for 3D printing changes the economic and technology choices for defence and aerospace. Now, if it’s a low production part, 3D printing is cheaper than running a mold or to create a mass batch.

Robotics:

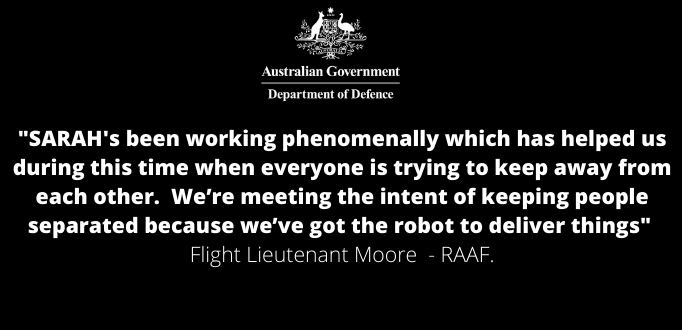

Now more than ever, defence industries are looking for innovative ways to be safer and more efficient. Robots introduces efficiencies by automating a simple part of the supply chain to free up people to do what only people can do.

3D printing and the new shape of industrial manufacturing, now making parts and tools stronger than ever, Defence and Aerospace industries are competing to make most of metal print applications.

Watch how Royal Australian Air Force has chosen Konica Minoltas Mobile Industrial Robots (MiR) to automate the movement of aircraft parts.

Discover the latest methods of metal printing which encases particles providing structural integrity, and recycling the needed particles for sustainability.

A precision-designed, sensor-driven machine delivers breakthrough reliability and performance with a simple user experience.

Read more about how printing Copper has recently become possible enabling disciplines such as electrical engineering to rethink creativity.